Gabions & Mattresses

Gabions & Mattresses

Key Features:

Ease Installation, Cost Effective

Application:

Bridge Protection, Slope Protective, Water Conservancy, Explosion

Download the company and product catalogue!

Product Details

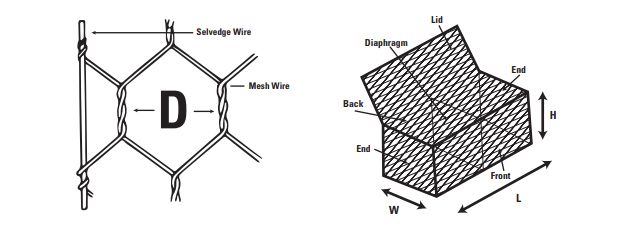

Gabions are sturdy rectangular baskets formed of hexagonal steel wire mesh. They are fortified by mesh diaphragms and a stronger wire selvedge. Gabions are frequently used to prevent erosion and retain earth.

They are flexible and ideally adapted to projects on shaky foundations, in contrast to rigid structures. Gabions are incredibly strong and require little upkeep. Our gabions are delivered flat-packed, ready for assembly and stone filling at the project site.

Finishing: Two types of wire to be chosen: Galvanized Wire and PVC Coated Wire (Grey Colour)

Finishing Goods such as Retaining wall, channel lining and weirs are fabricated by gabion.

Specifications:

| Gabion Cage | 1m x 1m x 1m , 2m x 1m x 1m , 3m x 1m x 1m 3m x 1m x 0.5m , 2m x 1m x 0.5m etc |

|---|---|

| Gabion Mattress | 6m x 2m x 0.5m , 6m x 2m x 0.3m , 6m x 2m x 0.23m , 6m x 2m x 0.17m 3m x 2m x 0.3m , 3m x 2m x 0.23m etc |

Wire:

- All tests on the wire mesh, lacing wire should be performed before manufacturing the mesh.

- The material MUST come from an ISO9001 certified factory

| Tensile Strength of wire (per BS 1052:1980 and EN10223-3) | 350 – 500 N/mm2 |

|---|---|

| Elongation (per EN10223-3) | <10% |

| Sample length | >25cm |

Zinc Coating:

| Adhesion of the zinc coating to the wire | As per EN 10244 (when the wire is warped sit turns around a mandrel having four times the diameter of the wire, it does not flake or crack when rubbing it with the bare fingers) |

|---|---|

| Physical characteristic of mesh wire | NO rusty spots on the part of the surface excluding the cut ends |

Test For Gabions:

Different tests to be carried on the gabion material are tabulated along with references and standards as follows:

| Dimension | References on Specifications | |

|---|---|---|

| Mesh Type | 8cm x 10cm | |

| Mesh Opening “D” mm | 80mm | ASTM A 975 |

| Nominal Dimension | 83mm x 114mm | ASTM A 975 |

| Mesh Wire Diameter Tolerance Zin Coating Min | 2.7mm (Inner Diameter) 3.7mm (Outer Diameter) ± 0.08mm 260 gsm | EN 10223 BS 1052 BS 443: 1982 |

| Selvage / Edge Wire Diameter Tolerance Zin Coating Min | 3.4mm (Inner Diameter) 4.4mm (Outside Diameter) ± 0.10mm 275 gsm | EN 10223 BS 1052 BS 443: 1982 |

| Lacing Wire Diameter Tolerance Zin Coating Min | 2.2mm (Inner Diameter) 3.2mm (Outside Diameter) ± 0.06mm 240 gsm | EN 10223 BS 1052 BS 443: 1982 |

Gabions & Mattresses (Con't):

| PVC COATING | References on Specifications | |

|---|---|---|

| Colour | GREY | |

| Thickness Nominal | 0.5MM | ASTM A 975 |

| Thickness Minimum | 0.38MM | ASTM A 975 |

| Specific Gravity | 1.32 | ASTM D 792 |

| Tensile Strength | Not Less Than 21 N/mm² | ASTM D 412 |

| Enogation At Break | Not Less Than 200% | ASTM D 412 |

| Modulus Of Elasticity | Not Less Than 19 N/mm² | ASTM D 412 |

| Hardnes | 50-60 Shore D | ASTM D 2240 |

| Abrassion Resistance | Less Than 220mm² | DIN 53516 |

| Salt Spray Exposure and Ultraviolet Light Exposure | The PVC shall show no effect after 1500 hours of salt spray exposure The PVC shall show no effect of exposure to ultraviolet light with test exposure of 2000 hours. After the salt spray test and exposure to ultraviolet light, the PVC coating shall not show cracks or noticeable change of colour, or blisters or splits. Also, the specific gravity and hardness shall not change more than 10% and 15% respectively from their initial values. | ASTM B 117-90 & ASTM D G53-88 |

(Available for customisation, subject to minimum order quantity)

Request a Quote

Simply fill out the form below and we'll be in touch as soon as possible